21. A dragline is required to remove 3,00,000 m3 of rock per month on the bank volume basis. Consider the following data for the dragline operation.

Effective working hours per month = 450

Bucket fill factor = 0.8

Cycle time = 65 s

Swell factor of the rock = 1.25

The minimum bucket capacity of the dragline in m3 is

Effective working hours per month = 450

Bucket fill factor = 0.8

Cycle time = 65 s

Swell factor of the rock = 1.25

The minimum bucket capacity of the dragline in m3 is

22. A shearer is deployed in a mine where the specific energy consumption for cutting coal is 800 kJ/m3. The specific gravity of coal is 1.2. If the machine produces 700 te/h, the electrical power consumption in kW of the shearer at 65% motor efficiency is

23. In an underground coal mine, a freshly exposed roof can be supported by a temporary support in the form of

24. A bucket wheel excavator with 20 buckets of capacity 0.5 m3 each, rotates at 5 rev/min. The bucket fill factor is 80%. The excavator loads on to 1200 mm wide belt conveyor. The cross-section area (m2) of the material on the belt is 0.1B2, where B is the belt width in m. The minimum speed of the belt in m/s to avoid spillage of material is

25. An ore block of length 30m and height 20m having an average width of 1.5m with sharp boundary walls is mined with a minimum mining width of 2m. If the tonnage factors are 3 t/m3 for ore, 2 t/m3 for wall rock and average grade of ore is 10%, the diluted grade of ore mined in percent is

26. In an overburden bench of an iron ore mine the following data were found:

Height = 10m

Burden = 4m

Spacing = 3m

Sub-grade drilling length = 1m

Collar stemming length = 3m

If the diameter of the explosive column is 150 mm and the specific gravity of explosive and that of rock are 0.9 and 2.4 respectively, the powder factor in te/kg will be

Height = 10m

Burden = 4m

Spacing = 3m

Sub-grade drilling length = 1m

Collar stemming length = 3m

If the diameter of the explosive column is 150 mm and the specific gravity of explosive and that of rock are 0.9 and 2.4 respectively, the powder factor in te/kg will be

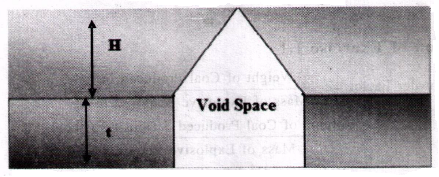

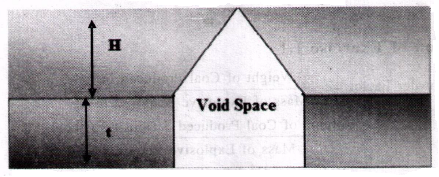

27. Cut & Fill stoping can be done by

28. A flat coal seam of thickness (t) 3m is excavated and broken roof rock has completely filled the space created due to extraction as shown in the figure. If the bulking factor of roof rock is 1.2. the caving height (H) in m is

29. In the order of the chronological development, the longwall support systems are arranged as

P Powered support

Q Link bar and friction support

R Frame support

S Hydraulic support

P Powered support

Q Link bar and friction support

R Frame support

S Hydraulic support